Product Overview

Keegan Precast Design, Manufacture and Install Precast Concrete Push Walls.

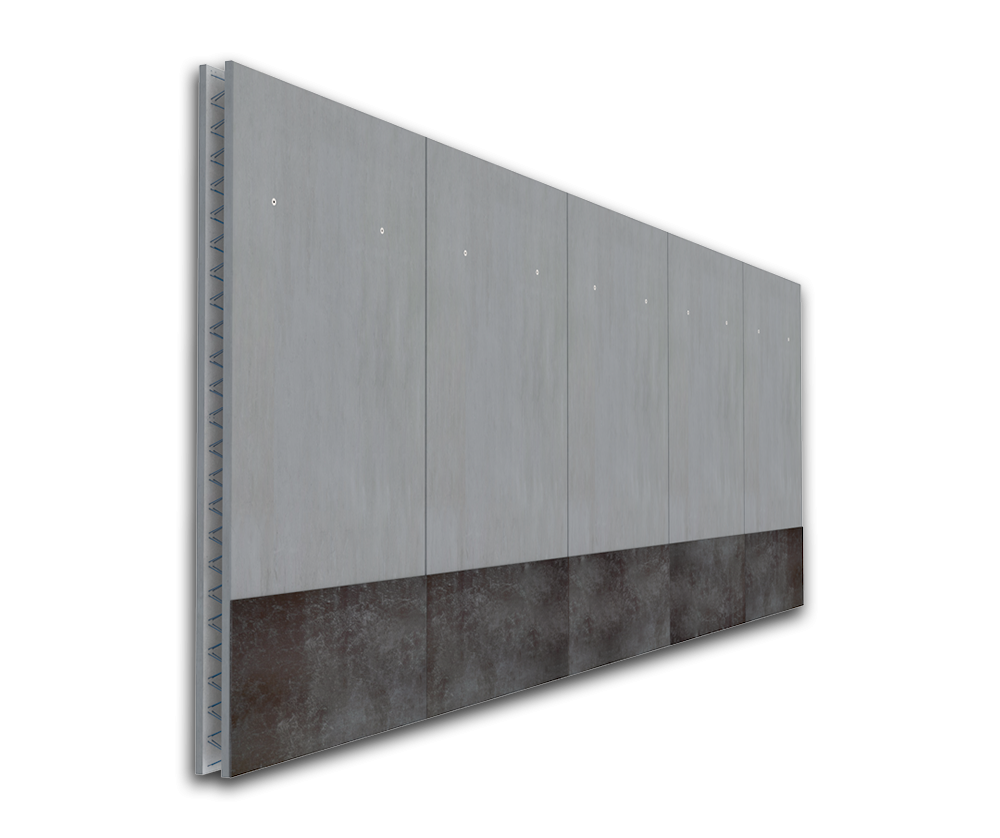

Our Precast Concrete Push Walls are individual wall panels typically used in waste recycling facilities or materials handling yards.

The manufacturing plant is capable of producing walls 11.5 m high in one continuous lift. Our maximum thickness wall in one production run is 400mm thick although our engineers have designed “back to back” push wall solutions for Waste Handling facilities where 750mm thick walls were required.

Our precast concrete push walls follow the same design principles as in-situ reinforced concrete push walls. We design the necessary reinforcement to suit the required bending moment. Our bespoke reinforced bar cutting machine only places the reinforced bar where it is required. This produces a very economic push wall solution.

Key Features

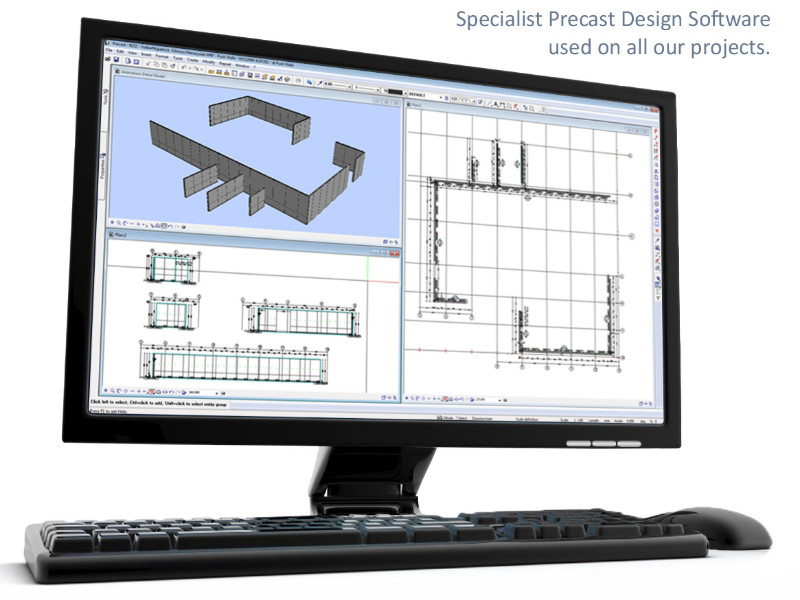

- Made to measure walls – design is carried out in-house

- Time saving – fast track construction method compared to block build

- Durable product – the composition of the product extends the lifespan

- High strength reinforced concrete to EN206 used in all Twin Wall

Keegans Precast Concrete Push Walls are ideal for use in Waste Recycling facilities, Salt Barns, Biomass Boiler Facilities and Bulk Materials Storage Yards.

Benefits

- Such as Flush fitting steel plates to protect against wear and tear from loading shovels or steel channels to the tops of walls can incorporated.

- Special additives can also be used in the manufacturing process to include air entrained concrete, GGBS (Ground-granulated blast furnace slag) or to provide resistance to Chlorine or Alkali attack.

Our tailor made precast wall range also includes;

We also design, manufacture and install tailor made precast filigree floor slabs.