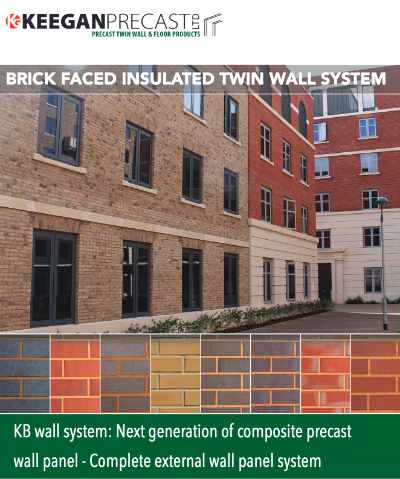

Product Overview

BRICK FACED INSULATED TWIN WALL

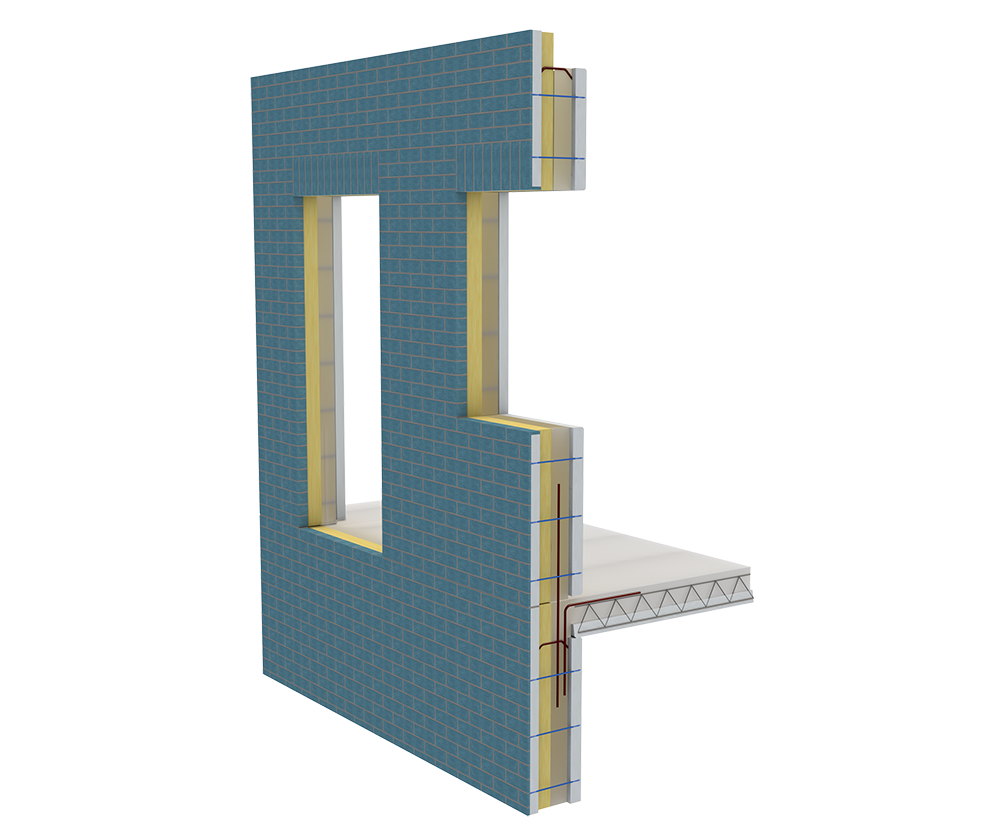

KB Walls are based on our tried and tested KC Wall (Insulated Twinwall) product. They are made using “ThermoMass” or similar wall panel ties under the German D.I.N. Zulasung Certification Process. The inner skin of the unit is cast on a fine polished steel pan and oscillated to achieve an exemplary finish. This differs to our competitors who use a power-float which provides an inconsistent finish.

The brick slips are placed directly into the standard mould the KB Wall is cast in. Layout, bonding and mix are set out at this point. The KB Wall panel is now cast exactly as normal with all quality checks and controls as would be expected from the standard KC Wall panel.

Both skins are tied together using the “ThermoMass” pultruded glass reinforced fibre rods. The wall panel is then filled with in-situ concrete on-site to provide a robust monolithic concrete structure. This system provides a combined inner leaf concrete structural load bearing wall while incorporating an insulated brick façade.

Key Features

- Standard brick sizes used 215mm x 65mm with stretcher bond as standard.

- Dove tail key cast in detail on back of brick slip

- CE certified product

- Reduced labour on site – less operatives required for erection process

- Insulated – wall panels with U Values as low as 0.1 W/m2K

- Reduced drying out time required – walls can be decorated immediately as the inner face is “Paint Ready”.

Benefits

- Complete finished external wall element ready to be placed on site

- The advantages of off-site construction with factory tolerances and high quality factory finishes

- The structural integrity equivalent to any in-situ designs

- The high levels of acoustic control and fire ratings that cannot be achieved by any other precast system

- Reduced staff on site – less operatives required for erecting walls

- The pre-installation of electrical conduits and outlets during production provides for faster construction of a building

- The speed of erection and certainty of programmed schedules

- The finished precast structure will have a monolithic quality that is unique to twin wall and will provide superior levels of air tightness

- Reduced drying out time required – walls can be decorated immediately.

Our tailor made precast wall range also includes;

We also design, manufacture and install tailor made precast filigree floor slabs.